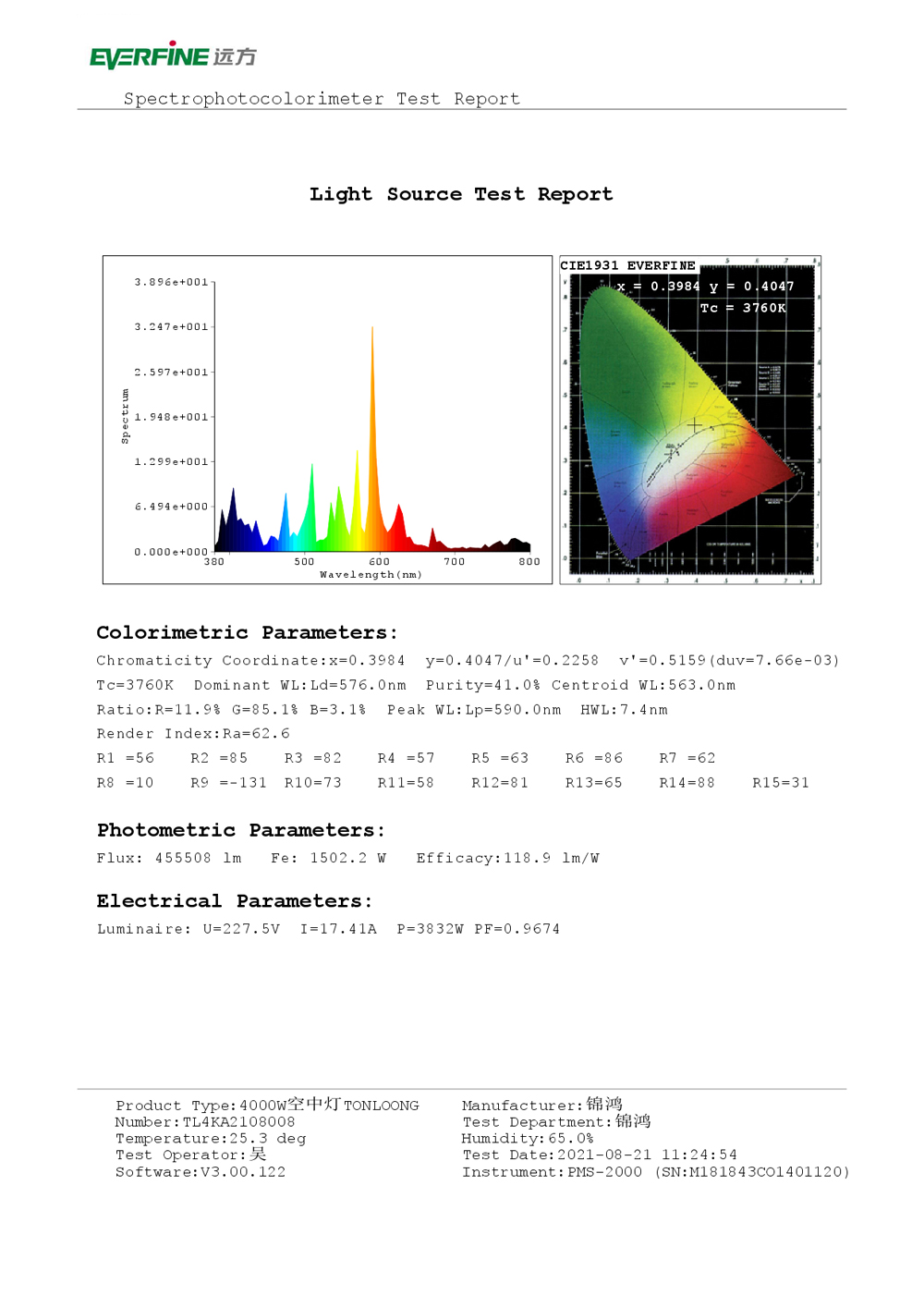

Product Parameters

|

Product Numbe |

Lamp holder |

Lamp Power [ W ] |

Lamp Voltage [ V ] |

Lamp Current [A ] |

STEEL Starting Voltage : |

|

TL-4KW/BT |

E40 |

3700W±5% |

230V±20 |

17 A |

[ V ] < 500V |

|

Lumens [Lm] |

Efficiencv [Lm/W ] |

Color Temp [ K ] |

Starting Time |

Re-starting Time |

Average Life |

|

455000Lm ±10% |

123Lm/W |

3600K/4000K/4800K/Custom |

5min |

18 min |

2000 Hr About 30% attenuation |

|

Weight[ g ] |

Packing quantity |

Net weight |

Gross weight |

Packaging Size |

Warranty |

|

About 1000g |

6 pcs |

6kg |

10.8 kg |

58×40×64cm |

18 months |

The Jin Hong Factory is regarded as a pioneer of high-quality professional lamps for fishing boats. Metal halide lamps are about 3 times brighter than similar tungsten halide lamps. These metal halide fishing lights have a color rendering index of over 90, making them the perfect combination of high efficiency and high color rendering for applications where color is critical.

Our production environment and equipment are the best in the industry. There are strict production control requirements, employees with years of working experience in fishing boats, technicians with 20 years of production of metal halide lamps, and senior technical staff are responsible for important operation positions in the factory.

We are proud to be the manufacturer of the top fishing boat lighting equipment. With output 1.5KW~4KW aerial lighting fishing lights and 2KW ~ 15KW underwater lighting fishing lights and other product series, there are white, red, green, blue four colors to choose from. Fishing lights with optimum luminous flux and color temperature

With more than 20 years of accumulated technology and knowledge, we produce fishing lamps with the best light flux and color temperature. It is exported all over the world, including to customers in Southeast Asia, China, Taiwan, Argentina as well as South Korea, Japan, and is used in many coastal and deep-sea fishing vessels. We ODM and sign NDAs for these clients.

Especially in China, our customers in Argentina, the largest deep-sea squid fishing ground, and the Pacific Ocean, boats equipped with Jinhong fishing lights have been recognized for their catch ranking and the quality of the lamps.

Question: what is the difference between the appearance of 4000W air lure lamp in the form of straight tube and ball?

Answer: the diameter of 4000W straight tube bulb shell is 110mm. The diameter of bulb shell in the form of ball is 180mm

Question: what is the difference between the upright and the ball form?

Answer: the volume of vertical bulbs is smaller than that of ball bulbs, which is convenient for handling, storage and installation.

The second start-up speed of vertical bulbs is slightly slower than that of spherical bulbs. Therefore, if the staff catch fish at night, they need to turn on the light for many times, turn off the light and turn it on again,We suggest you opt for spherical fishing lights

Certificate

PHLOONG Factory Advantages

Source factory, integrated industry and trade, dual advantages of cost and efficiency

We have our own factory, which integrates R&D, mold development, light bulb accessories, light bulb tubes, assembly, and quality control. By eliminating the middleman, we ensure that you get the most competitive factory price and a more agile delivery response.

Frequently Asked Questions

From a grain of quartz raw material to a precision electronic component, and finally to the finished lighting fixture, all key production processes are completed in our own factories. This vertically integrated model gives us absolute control over raw material selection, production processes, and quality standards, ensuring that every product meets stringent requirements.

Equipped with an automated light tube production line and a high-standard dust-free assembly workshop. Under the control of precision electronic equipment, pill injection and special gas filling are more accurate and efficient, ensuring stable quality of the core light tubes. The manual assembly process follows strict SOPs and combines multiple inspections to ensure that the core performance of each lamp, such as luminous efficiency, battery life, and waterproofing, is stable and reliable.

We have established a comprehensive quality management system that spans the entire process from R&D, incoming materials, manufacturing, to finished products. We have professional testing equipment and laboratories (as shown on our website) to strictly control parameters such as luminous flux, color temperature, waterproof rating (IPX8) (with corresponding sealed lighting fixtures), aging tests, and underwater lighting pressure tests. Our products comply with safety and environmental standards for fishing vessels, helping you enter your target market with confidence.

With over a decade of experience in the fishing tackle and lighting industry, we have a team of experienced engineers. We not only focus on the continuous optimization of existing products, but also provide professional ODM/OEM solutions based on your market insights and unique needs, working together to develop new products that lead the market.

With the flexibility of our own factory, we can quickly respond to small and medium-sized orders and guarantee stable delivery of large orders. We can flexibly accommodate your trial orders, repeat orders, or peak season demands to seize market opportunities together.

Only medical-grade clean workshop in the country

25 years of lighting manufacturing technical expertise combined with the only medical-grade clean workshop in the country lay the foundation for our products:

We have a professional lighting design and development team and modern medical-grade high-cleanliness workshops. We are able to efficiently complete the stability of product light sources and the perfect welding and production of precision structural components, ensuring that the product structure is sturdy, the appearance is exquisite, and the dimensions are accurate, laying a solid foundation for the reliability and durability of the lighting fixtures.

Sample Room

Quartz Accessories Workshop

Precision Workshop

Welding Workshop

Light Arc Manufacturing Workshop

Light Arc Materials Workshop

PHLOONG Service Advantages

One-stop service, hassle-free and efficient cooperation

From concept communication, design prototyping, mass production manufacturing to quality inspection and shipment, we provide a one-stop service throughout the entire process. You only need to contact us through a single point of contact to efficiently resolve all issues related to product manufacturing, significantly reducing communication and management costs.

1. One-stop service, hassle-free and efficient cooperation

Factory-direct company, with costs reduced by 15%+

“We are not middlemen; every penny you pay goes directly into the product itself.

With our own raw material production workshops, HID tube production lines, and assembly lines, we eliminate all markups in the supply chain,

offering you the advantage of factory-direct pricing. Compared to similar products, you save over 15% on costs.

✓ Customer benefits: Access fishing lights comparable to Japanese and Korean brands, with competitive end-user pricing and greater profit margins.

✓ Secure a competitive edge in the market and maintain momentum during peak seasons!

2. From R&D to shipment, response time accelerated by 50%

Factory-direct company, with costs reduced by 15%+

"Engineers and workshops are separated by just a wall:

Molds can be adjusted on the same day as sample confirmation, and order inquiries can reach production line managers within 2 hours.

Urgent orders can trigger *dedicated production line insertion*.

Say goodbye to cross-company communication inefficiencies and improve decision-making efficiency by 50%."

✓ Customer benefits: Seize market opportunities and avoid stockouts during peak seasons

✓ We are the only factory in the industry with full vertical integration and control over the entire fishing light supply chain.

✓ We have mature production lines, and our warehouses always have stock available for standard products.

3. Full control of the entire chain, 0 compromise on quality

"From quartz tube raw materials to finished lamps, “95% of the process is completed in-house”

The light tube workshop monitors temperature and humidity in real time (see workshop environment diagram).

Aging tests start at 2,000 hours (see aging test room video).

✓ Customer benefits: Eliminate the risk of substandard workmanship, reducing return rates by 80%.

PHLOONG Warehouse

PHLOONG Customer Use Case